What are you looking for?

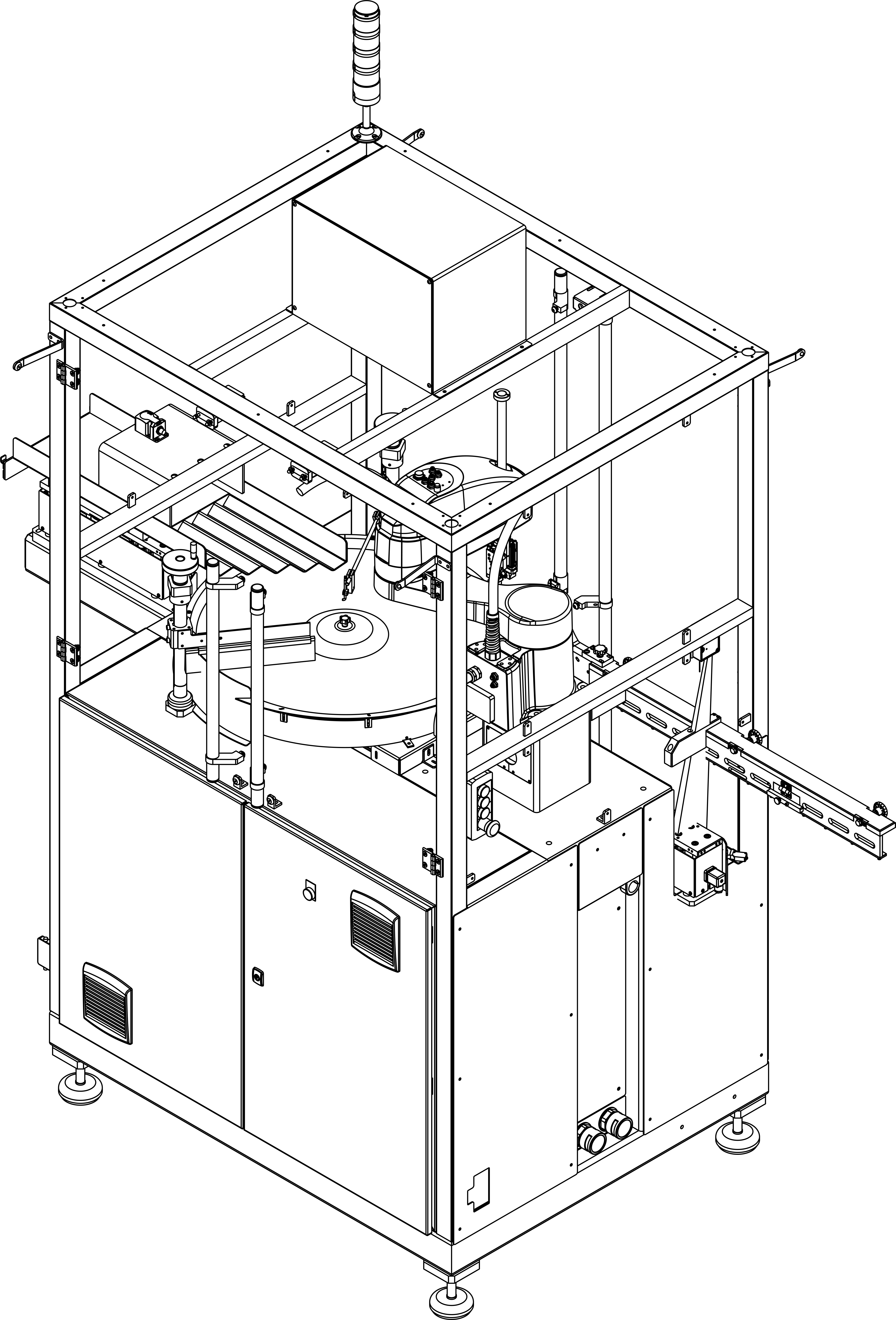

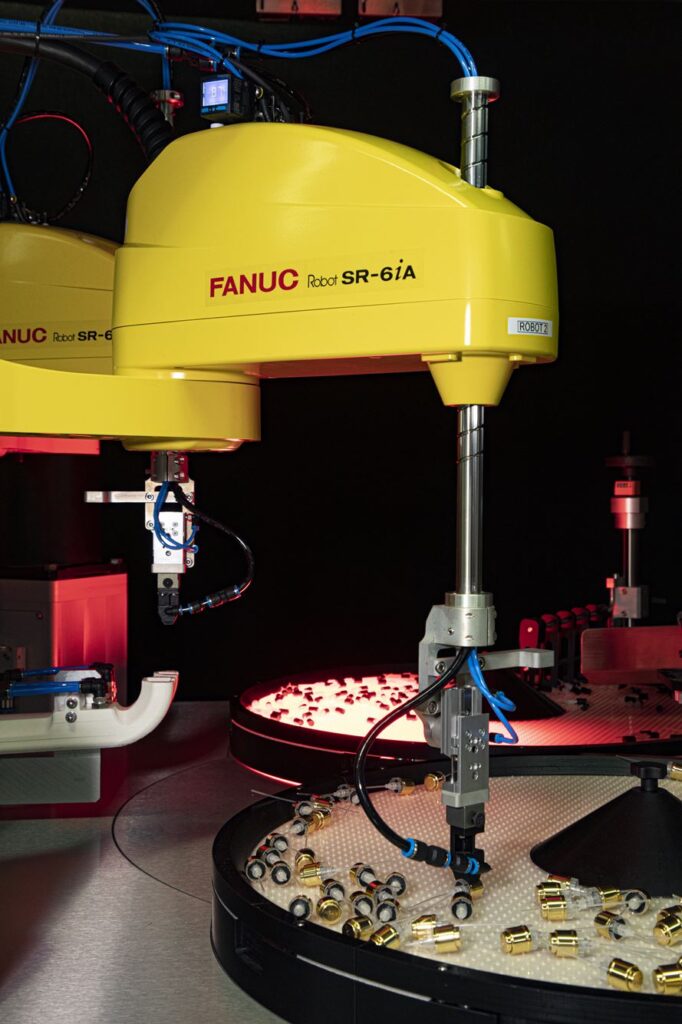

Flexi 200

Main Benefits

-

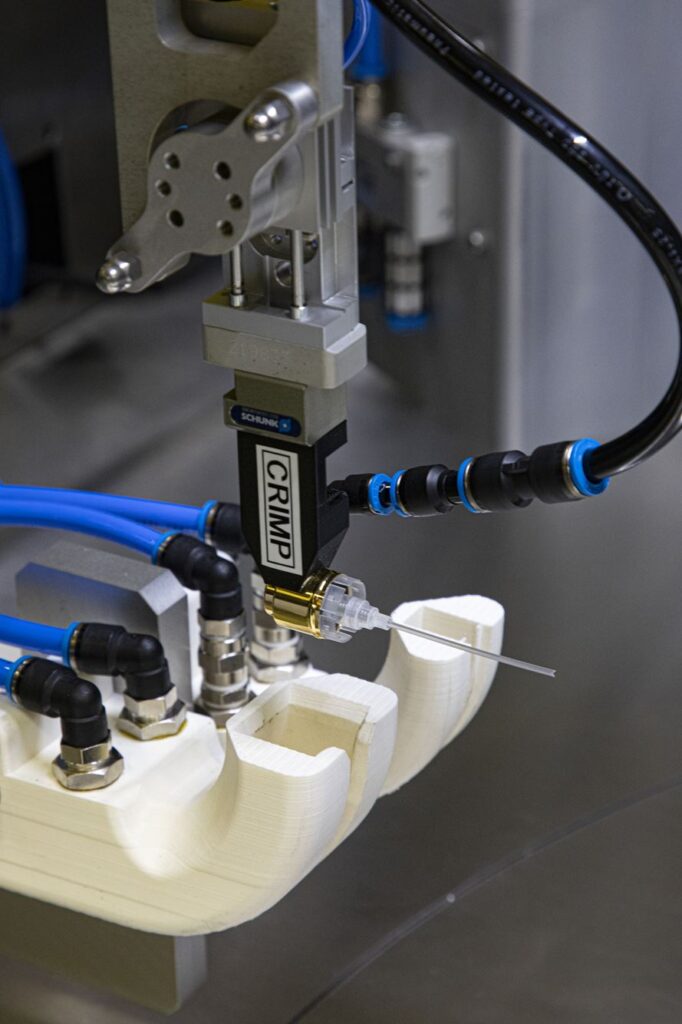

In single robot format, the robot picks components from a back-light rotating disc, orientates them, and deposits them at a rate of up to 120 cpm (60 cpm per robot)

-

Through extensive testing, industrial experience, and know-how, PKB has a solid understanding of the advantages and limitations of this technology

-

The compact footprint allows the Flexi 200 to replace an existing mechanical distribution

-

PKB can test and create new format parts, vision settings, and speed tests at our factory for “turn-key” service on additional formats

-

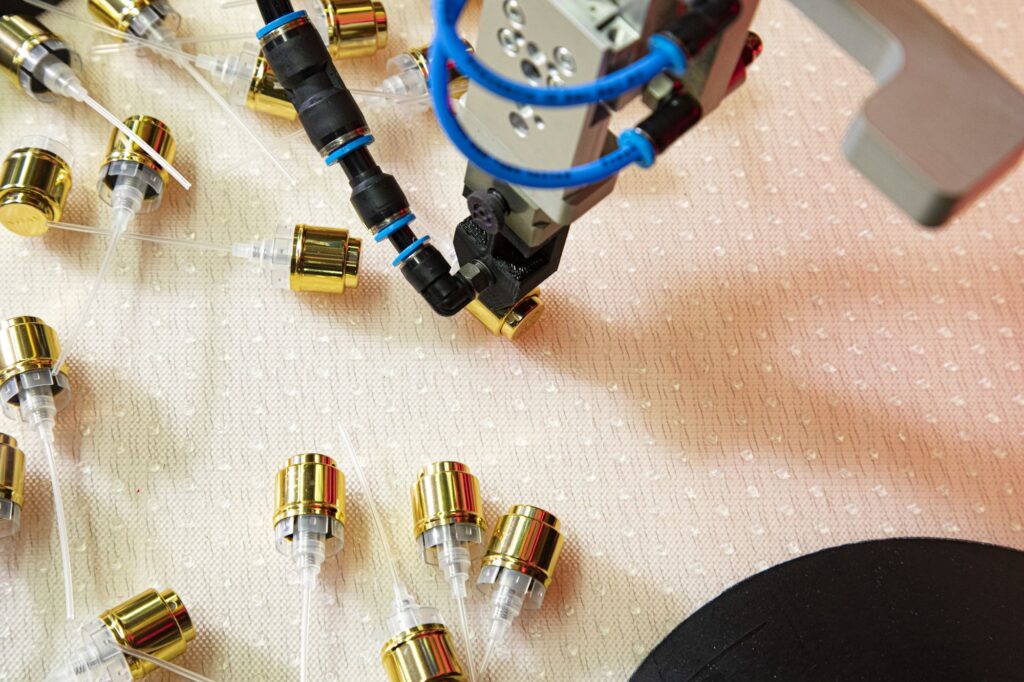

Replaceable surface texture of rotating disc to adapt to particular component geometries

-

Aggressive lead-time

Types of packaging

Component types

01

Perfume pumps

02

Cosmetic pumps (including nozzle orientation)

03

Caps and lids

04

Reducers

05

Nail varnish, mascara and lip-gloss brushes (with or without integrated cap)

06

Droppers

07

Roll-on

Tech

specs

specs

| Output | Up to 60 components/minute for single robot version |

| Electricity supply | motors machine: 2.5 kW |

| Compressed air | Flow rate: 15 Nm3/h |

| Working height | 1250 mm |

| Dimensions (single robot) | Width: 1025 mm |

| Approximate weight | single: 800 kg |

| Sound level | < 75 dB A |