What are you looking for?

Eko

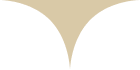

Meet our Flagship: The Eko Line

-

Reflecting PKB's decades-long expertise in the field, the EKO is equipped with high quality servo technologies and a robust design, which allows it to be one of the most versatile, compact, economical, and reliable machines in the industry

-

Ideal for small runs and frequent changeovers, the EKO combines maximum precision with practicality

-

An excellent long-term investment that could be delivered to your doorstep in the blink of an eye

-

The EKO can be configured to fill any product and can handle a very large range of assembly. The EKO can easily be adapted from one configuration to another, by the client, in the factory

-

Can be combined with Plug and Play distribution systems, for stage-wise automation and investment

-

The EKO can be combined with PKB machinery upstream and downstream:

01 Robotic loading and unloading of bottles02 Marking and detection machine (labeling, ink-jet, quality inspection, and control)

-

The result is a full primary packing line with an exceptionally compact footprint, delivery time, and performance

Recommended for

Perfume

Cosmetic creams

Liquid cosmetics

Hair dye

Types of packaging

Functions available to integrate

Handling

Cleaning

Filling

Marking

Capping

Other

Options

01

Dust remover

02

Servo-driven filling pumps

03

Servo-driven bottom-up filling nozzle

04

Jar rotation

05

Servo-driven torquing

06

Buffer tank

07

Automatic overflow (perfumes), the surplus liquid may be re-routed back to the filling tank via an automatic return system (exclusive

08

Removable automatic pump feeder (TRD)

09

Removable automatic collar feeder (TRD)

10

Nail varnish: insertion of beads/balls, brushes, screw-on caps

11

Jars: Aluminum foil placing, pre-sealing, sealing

12

Mechanical or Robotic feeding (2 assembly stations)

13

Diagnostics and remote maintenance assistance via Ethernet

14

Depucking via a parallel belt or Cobot

Tech

specs

specs

| Output | Up to 40 upm |

| Filling volume | 0.5 ml to 500 ml |

| Bottle height | max: 250 mm |

| Accuracy | ± 0.5% |

| Electricity supply | Power: 3 × 400 V+N – 50/60 Hz |

| Compressed air | Flow rate: 25 Nm3/h |

| Working height | 950 mm |

| Dimensions | Width: 1800 mm |

| Approximate weight | Net: 1000 kg |

| Sound level | < 75 dB A |